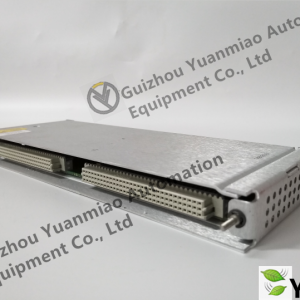

BENTLY 3500/50 286566-02 Vibration Monitoring Module

Engineered for industrial environments where machinery reliability is critical, the BENTLY 3500/50 286566-02 vibration monitoring module delivers precise detection of mechanical anomalies in rotating equipment. Its primary role? Catching subtle vibration shifts before they escalate into costly failures, particularly in applications like turbines, compressors, and pumps.

| Specification | Details |

| Brand | BENTLY NEVADA |

| Model | 3500/50 |

| Sub-model | 286566-02 |

| Voltage | 110/220V AC |

| Frequency Range | 10–1000 Hz |

| Sensitivity | 50 mV/g |

| Operating Temp | -40°C to +85°C |

| Certifications | CE, UL, ATEX |

Field engineers often deploy this module in power plants, offshore rigs, and chemical processing facilities where vibration analysis is non-negotiable. For instance, in a natural gas compressor station, the 3500/50 works alongside BENTLY’s 3500/22M and 3500/44 monitoring cards to create a layered protection system. The 286566-02’s compatibility with both legacy 3300 systems and newer 1900 platforms makes it a go-to upgrade option when enhancing existing setups without full system overhauls.

What sets this module apart isn’t just its ±5% frequency response accuracy, but its ruggedized design. The aluminum housing with IP65 rating resists corrosion in high-humidity environments—a common pain point in offshore installations. Unlike generic vibration sensors, the 3500/50 integrates seamlessly with BENTLY’s Asset Condition Monitoring (ACM) software, enabling real-time diagnostics without third-party middleware. The dual-channel architecture also allows redundancy, where one channel can take over if the other detects a fault—this matters when unplanned shutdowns could cost millions.

While vibration monitoring isn’t glamorous, the 3500/50 quietly earns its keep. Its ability to operate across extreme temperatures (-40°C to +85°C) means it survives in desert oil fields and Arctic LNG plants alike. The 50 mV/g sensitivity isn’t just a spec—it translates to catching bearing wear at Stage 1, years before catastrophic failure. When paired with BENTLY’s 3500/92 relay module, maintenance teams get actionable alerts with less than 1ms latency. In short: less downtime, more peace of mind.

Reviews

There are no reviews yet.