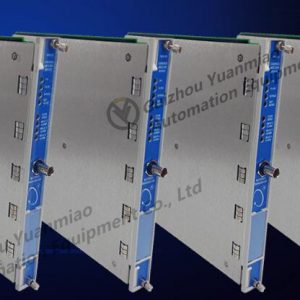

BENTLY 3500/05-01-01-01-00-00 Vibration Monitoring System

Engineered for heavy-duty industrial environments, the BENTLY 3500/05-01-01-01-00-00 Vibration Monitoring System delivers continuous, high-precision vibration analysis for rotating machinery. Originally developed for power generation and oil & gas sectors, this system acts as a critical safeguard against bearing failures, rotor imbalances, and other mechanical anomalies that could lead to catastrophic equipment damage.

Technical Specifications

Manufacturer: Bently Nevada

Model Number: 3500/05-01-01-01-00-00

Voltage Requirement: 220 VAC

Signal Frequency: 50 kHz

Certifications: CE, ISO 13373

Mounting: DIN Rail

This monitoring system has become an industry standard for turbomachinery protection in facilities like gas compressor stations and steam turbine plants. Our customers frequently pair it with complementary Bently Nevada components such as the 3500/22M proximity system and 3500/92 relay modules. One refinery maintenance engineer mentioned how it detected early-stage shaft misalignment in a critical feed pump, preventing an estimated $150k in repair costs during a scheduled shutdown.

What sets this system apart is its dual-channel redundancy design and compatibility with legacy Bently 3300 systems. The modular architecture allows hot-swapping of faulted components without system shutdown. Its 24/7 vibration data logging capability integrates seamlessly with plant historians like OSIsoft PI, and the built-in self-diagnostics flag sensor health issues before they become critical. For harsh environments, the conformal-coated circuit boards resist vibration fatigue and corrosion.

While not the most compact vibration monitoring solution, its field-proven reliability in extreme conditions makes it a preferred choice for mission-critical applications. The system’s longevity – with many units operating continuously for over 15 years – combined with its straightforward calibration process, delivers exceptional value compared to newer but less proven alternatives.

Reviews

There are no reviews yet.