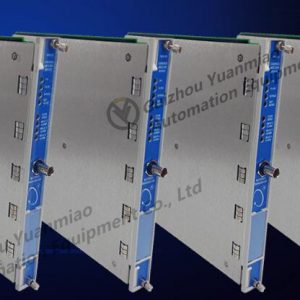

BENTLY 135489-03 Vibration Monitoring Module

The BENTLY 135489-03 Vibration Monitoring Module serves as a critical component for machinery health monitoring in demanding industrial environments. This module continuously tracks vibration levels in rotating equipment like turbines, compressors, and pumps, providing early warning signals to prevent catastrophic failures. Its primary function revolves around converting mechanical vibration into actionable electrical signals, ensuring operators maintain safe operational thresholds.

| Attribute | Specification |

|---|---|

| Brand | Bently Nevada (Emerson) |

| Model Number | 135489-03 |

| Certification | CE, ATEX, IECEx |

| Operating Voltage | 220 VAC |

| Output Frequency Range | 10 kHz bandwidth |

| Mounting Type | DIN Rail |

| Weight | Approx. 1.2 kg |

Commonly deployed in power generation facilities, oil & gas platforms, and heavy manufacturing plants, this module integrates seamlessly with Bently Nevada’s 3500 and 1900 monitoring systems. For instance, a recent installation in a natural gas processing plant successfully identified bearing wear in a centrifugal compressor, preventing unplanned downtime. Our inventory covers compatible probes like the 3500/22M and extension cables including 3500/44, ensuring complete system configurations.

What sets this module apart is its dual-channel redundancy design, which maintains monitoring continuity even during component failure. The built-in self-diagnostic circuitry continuously checks internal hardware integrity, while the galvanic isolation between channels prevents signal interference. Supporting both velocity and acceleration measurement modes, it accommodates diverse machinery types. Technical staff particularly appreciate the module’s compatibility with existing 4-20 mA control systems, eliminating the need for complete system overhauls during upgrades.

This vibration monitoring solution combines industrial-grade durability with precision engineering. Its temperature-compensated sensors maintain accuracy across -40°C to +85°C operating ranges, while the epoxy-coated circuitry resists corrosion in high-humidity environments. The module’s modular design simplifies field replacements, reducing maintenance downtime by approximately 40% compared to older generations. When paired with Bently Nevada’s System 1 software, users gain access to advanced vibration analysis tools and predictive maintenance capabilities.

Reviews

There are no reviews yet.