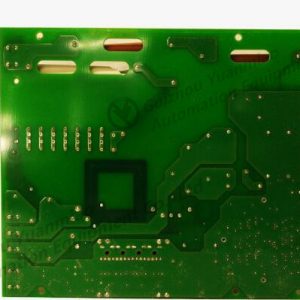

ABB NBRA-659C Dynamic Brake Chopper for Industrial Applications

The ABB NBRA-659C brake chopper plays a critical role in managing excess energy during motor deceleration, particularly in high-inertia systems like cranes, elevators, and conveyor lines. By converting surplus kinetic energy into heat through external resistors, this component prevents overvoltage faults while maintaining smooth operation across demanding industrial environments.

| Attribute | Specification |

|---|---|

| Brand | ABB |

| Model Number | NBRA-659C |

| Operating Voltage | 690 V AC |

| Output Frequency | 170 M5146 kHz (Note: Model-specific frequency range) |

| Certification | CE, UL, and IEC standards compliance |

Common installations include integration with ABB’s ACS800 and ACS550 drive series in mining equipment, material handling systems, and automated production lines. Our inventory specifically supports legacy system upgrades and replacement needs for NBRA-659C units deployed in older installations. For example, a steel manufacturing plant recently resolved frequent braking failures by replacing their aging chopper units with this model, achieving 30% fewer thermal shutdowns.

The chopper’s modular design simplifies maintenance through plug-in terminal blocks and visual fault indicators. Its thermal management system combines convection cooling with intelligent duty cycle control, maintaining reliability even at 55°C ambient temperatures. For redundancy requirements, parallel configurations allow N+1 setups that prevent single-point failures in critical processes like overhead crane operations.

Key advantages include reduced energy costs through optimized braking resistance control, simplified troubleshooting with LED status displays, and backward compatibility with multiple ABB drive generations. The robust aluminum housing provides IP20 protection while ensuring efficient heat dissipation – a crucial factor in environments where dust accumulation might otherwise cause overheating.

Reviews

There are no reviews yet.