Attention: Due to the large number of products from our company, the pictures cannot match each other. Please contact me to confirm the actual product!

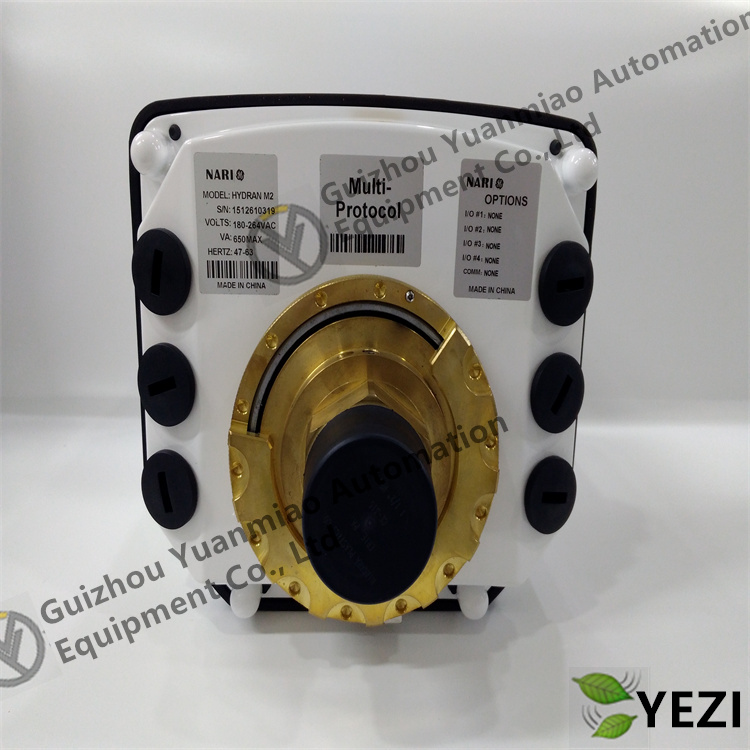

HYDRAN M2 is a device launched by GE for continuous online monitoring of dissolved gases and moisture levels in transformer oil. It serves as an early warning system for transformer fault conditions. Here are its detailed specifications:

- Additional Sensor Connectivity: It allows connection of additional sensors such as top and bottom tank oil temperatures, transformer load, or ambient temperature. By correlating their data with dissolved gas analysis and humidity values, it enables more comprehensive analysis.

- Onboard Computing Function: Utilizes a transformer mathematical model based on IEEE standards to convert raw data into useful condition information, providing in-depth insights into transformer status.

- Multiple Communication Methods: Equipped with a local LCD display for on-site monitoring. It supports digital communication protocols such as Hydran, Modbus, and DNP 3.0, and communication methods including RS-485, modem, Ethernet, and optical fiber. Additionally, optional 4-20mA analog outputs and dry contact relays are available for further integration.

- Configurable Alarms: Features two alarm levels (Alert and Alarm), which can be set based on sensor readings or calculated transformer models to alert users to abnormal levels of fault gases or moisture.

- Mark III Version Improvements: Updated electronic boards and power supplies to meet RoHS requirements, addressing obsolescence issues. It offers improved sensors, global power supply compatibility, support for up to 4 optional input/output cards, and internal multimode fiber optic communication, among other functions.

It can measure common fault gases such as hydrogen, carbon monoxide, acetylene, and ethylene, as well as the water content in oil, which indicates insulation degradation or gasket leaks, etc.

- Asset Supervision: Suitable for permanent installation on a single transformer oil valve without the need for additional pipes or pumps. It can detect gas and moisture content, providing a basis for asset condition assessment.

- Power Facilities: Provides an integrated solution for critical medium-sized transformers, helping to prioritize asset replacement strategies.

- Industrial Plants: Can reduce the risk of process interruptions caused by power failures and minimize costly production downtime.

- Operating Voltage: 100-240VAC

- Operating Frequency: 50-60Hz

- Operating Temperature: -40°C – +85°C

Related products:

| GE |

IC200GBI001 |

| GE |

IC3645LXCD1 |

| GE |

IC660BBD025 |

| GE |

IC660EBD020 |

| GE |

IC660ELB912G |

| GE |

IC660ELD100A |

| GE |

IC660TSA100 |

| GE |

IC670CBL001 |

| GE |

IC670CHS001 |

| GE |

IC670CHS002 |

[Disclaimer]

Our company sells new products and discontinued products, and purchases such special products through independent channels. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products of this website. All product names/product images, trademarks, brands and microlabels used on this website are the property of their respective owners. Product descriptions, descriptions or sales with these name images, trademarks, brands and logos are for identification purposes only and do not represent any association or authorization with any right holders.

Reviews

There are no reviews yet.